Project Profile

Scheme design--installation and commissioning

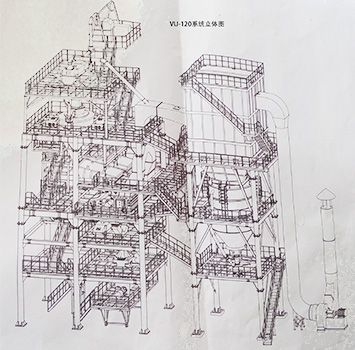

The use of highly-intensive fully-closed tower-like layout integrates the high-efficiency sand-making system, particle shape optimization, stone powder control, grading adjustment, water content control and environmental protection, which can optimize and adjust the indexes like the particle shape, grading, powder content and fineness modulus so that machine-made sand can completely replace natural sand in concrete and mortar preparation. The performance of machine-made sand gets improved and the cement as well as additives can be saved a lot.

Project Background

Policy Factor

Since the launch of Technical Regulations of Concrete Prepared by Machine-made Sand by China's Ministry of Housing and Urban-Rural Construction (MHURC) in 1973, machine-made sand has been developed extensively. Besides, the development of machine-made sand is deeply influenced by the macro-control policy, industrialization, B&R initiative, urbanization and ecological management.

Environment Factor

The cost for quarrying natural sand gets higher and higher while the amount gets less and less because of excessive quarrying. Natural sand is non-renewable resource, so, to keep natural terrains and protect river wall as well as the ecological balance, the natural sand quarrying has been prohibited in some regions.

Under the influence of policy and environment, some relevant enterprises are encouraged to develop machine-made sand production so as to protect the ecological environment in Shijiazhuang, Hebei.

Performance Standard

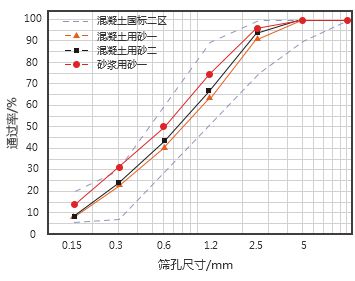

The sand produced by VU meets the standards of GB/T14684 and JGJ52. The sand can be adjusted according to the practical requirements. The fineness modulus can be controlled within 2.0-3.5; the powder content 3-15%.

| Screen size | Concrete sand 1 | Concrete sand 2 | Mortar sand 1 | International bound of concrete sand | ||||

|---|---|---|---|---|---|---|---|---|

| Unit screening rate | Accumulated screening rate | Unit screening rate | Accumulated screening rate | Unit screening rate | Accumulated screening rate | Unit screening rate | Accumulated screening rate | |

| 4.75 | 0 | 0 | 0 | 0 | 0 | 0 | 10% | 0% |

| 2.36 | 9.5% | 9.5% | 5.3% | 5.3% | 3.5% | 3.5% | 25% | 0% |

| 1.18 | 26.8% | 36.3% | 27.6% | 32.9% | 22.0% | 25.5% | 50% | 10% |

| 0.6 | 22.9% | 59.3% | 23.7% | 56.6% | 24.5% | 50.0% | 70% | 41% |

| 0.3 | 17.8% | 77.1% | 19.2% | 75.8% | 18.5% | 68.5% | 92% | 70% |

| 0.15 | 14.6% | 91.7% | 15.5% | 91.3% | 17.5% | 86.0% | 94% | 80% |

| 0.075 | 3.9% | 95.6% | 4.5% | 95.8% | 9.3% | 95.3% | -- | -- |

| Chassis | 4.4% | 100% | 4.2% | 100% | 4.7% | 100% | -- | -- |

| Fineness modulus | 2.74 | 2.61 | 2.33 | |||||

Equipment in the Production Line

Based on over 30-year experience in this industry, SBM spent 5 years developing VU system at the specialized aggregate optimization test site to satisfy the increasing demand for high quality sand and the performance requirement of concrete and mortar. VU Aggregate Optimization System is a scheme system designed to produce high quality machine-made sand which overcomes the problems in the sand-making technology including crushing, grinding and separating. In this production line, VU Aggregate Optimization System perfectly met all the machine-made sand production standards of Shijiazhuang Hengxin Jinshuo Construction Material Company.

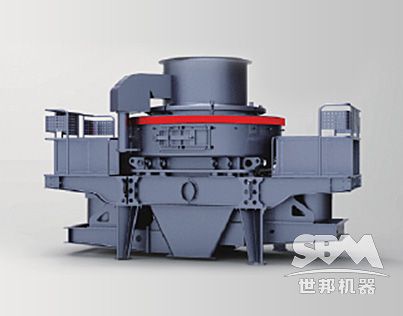

VU Sand Making Crusher

The new grinding and dressing effect can effectively eliminate the elongated and flaky particles and remove the edges of sand, which makes the shape of finished sand product improved substantially.

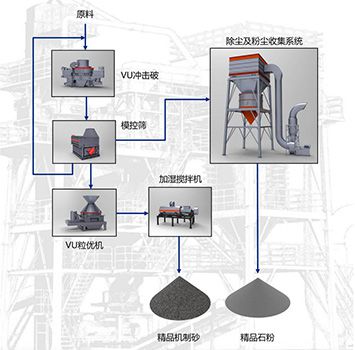

VU FM (Fineness Modulus) Control Screen

The perfect combination of screening and beneficiation makes the fineness and modulus controllable. Connecting the mature theories of crushing, screening and beneficiation and based on the design of full-closure, dust-collecting via negative pressure and screening evenly ,the tasks of material screening and dust removing can be finished on a single machine excellently at the same time, greatly increasing the productivity and avoiding the problems existing in traditional dry-type screening technologies like dust and sludge treatment.

Moisture Content Control Machine

Automated control design guarantees the stable water adding to keep the eligible water content of final sand and the uniformity, and to avoid segregation.

Dust Separating and Collecting System

The negative pressure dust collector is used. The closed operation in the whole process including the transportation from fine ore bin to powder tank car is to ensure the dust-free site and the attainment of national environmental standard.

VU Particle Shape Optimization Machine

The world's first efficient particle type optimization technology, imitating formation principle of natural sand, the machine adopts the global pioneering technologies of "low energy crushing and dressing" and "self-grinding via falling mode" that can validly remove the edges on the surface of final products and increase the volume of fine sand of -0.6mm so that the grading and particle shape can get optimization. And the voidage reduces 1-2%; the flow time 5%.

Central Control System

Setting and keeping the optimal operating parameters is available. And the quality of products is stable. This system can maximize the productivity and keep the overall efficiency at the highest level.

Technology Analysis

After being crushed and shaped by the VU Sand-making Crusher, the tailings below 10mm as raw materials are divided into three components under the action of FM Control Screen and Dust Collector--- stone powder, reverting material and finished sand product. Stone powder is collected by Dust Collector and stored at the fine ore bin while the finished sand product enters the Particle Shape Optimization Machine for further dressing and then is taken the last processing step--- mixing in humid environment. Processed by VU Aggregate Optimization System, raw materials can be turned into high-quality sand with reasonable grading, smooth shape and controllable powder content, and dry, clean, recycled and high-quality stone powder (Application fields depend on raw materials).

Advantages of Production Line

The VU Aggregate Optimization System---- a world-leading dry-type sand-making system designed by SBM for machine-made sand production of Shijiazhuang Hengxin Jinshuo Construction Material Company was upgraded fully on the basis of the existing dry-type sand-making system. The use of highly-intensive fully-closed tower-like layout integrates the high-efficiency sand-making system, particle shape optimization, stone powder control, grading adjustment, water content control and environmental protection. Not only does the productivity increase a lot, but also all standards including particle shape, grading and powder content improves so that the performance of machine-made sand can be compared with natural sand and new chances and value in the development of sandstone, cement and concrete industry are created.

High Environmental Protection

A. Environmental technology: The fully closed transportation and production and the negative pressure dust removing design avoids raising dust in production sites. The dry-type production and screening technology avoids the emission of waste water and slush.

B. Environmental operation: Moisture Content Control Machine(optional) keeps the water content of finished sand product qualified and avoids raising dust. The powder storehouse monitoring and automatic telescopic material discharging design prevent the stone powder from spilling in transit. Besides, the dry-type dust removing and separating technology keeps the dryness and cleanness of stone powder, making the treatment and overall utilization easier.

High Efficiency

A. Efficient production: The all-around innovation of crushing and grinding technologies increases the sand production rate by over 10%. The integrated dry-type screening technology elevates the screening efficiency obviously and the screen area can be reduced by over 50% compared with that of traditional technology. The performance improvement of single machine and the reasonable use of technologies reduce the electricity consumption a lot and increase the processing volume by 5-10%.

B. Efficient operation: The intensive tower-like design occupies smaller floor areas. For example, an area of 7.5m×24m can place the body part of VU70. The new anti-abrasive design and the upgrading of materials prolong the life span of wear-resistant parts and reduce the maintenance downtime a lot. The integrated control system and online adjustment design can adjust the system settings in operation, increasing the quality and yield of finished sand product and reducing labor force.

High Quality

A. Reasonable grading: Integrated crushing & grinding functions and flexible screening design make the grading of finished sand product continuous, adjustable and controllable. The fine sand within 0.15-0.6mm increases sharply while the coarse sand with fineness within 2.36-4.75mm reduces relatively. The grading meets the American standard ASTMC33、the secondary level of Chinese standard JGJ52 and Indian standard IS383.

B. Smooth particle shape: Completely original grinding and material falling shaping technologies mainly produce square and spherical sand. The edges on the sand surface are reduced to the extreme. Meanwhile, the superficial area and voidage decreases obviously and the fluidity is therefore increased.

C. Controllable powder content: dry-type powder removing technology keeps powder content of finished sand product (0-0.15mm) stable and controllable within 3-15%. The dry and clean stone powder got by dry-type separation method can be recycled.

High Profit

Highly-efficient system design reduces electricity consumption by 5-10% and labor cost by 40%. The one-time investment can save cost over 30% in comparison with similar products.

Benefit Evaluation

Economic benefit evaluation

The raw materials are relatively clean low-value stone chips with fineness within 0-5mm and 5-10mm. The 0-5mm stone powder before being processed is 4 yuan per ton while the processed high-quality machine-made sand is 45 yuan per ton with the value of tailings increasing by 40 yuan per ton.

Performance benefit evaluation

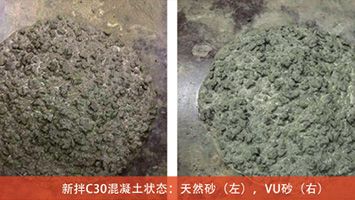

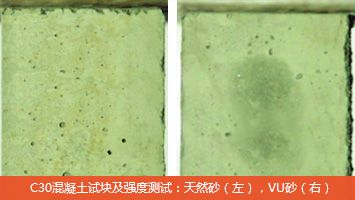

The application effect of machine-made sand concrete produced by VU120 Aggregate Optimization System is far better than that of natural sand.

Sand produced by VU system can completely replace natural sand to prepare C20-C60 concrete and other special kinds of concrete. The machine-made sand has high strength, wide applicable performances and can save the use of cement and additives.

Why was VU Aggregate Optimization System from SBM frequently selected?

Project manager feedback on installation

1. The whole VU system is over 25 meters high. It is a heavy engineering project which must strictly observe the national safe regulations and be finished by following the drawing requirements.

2. Receiving related data of VU system, the plan for installation must be enacted in advance. According to the size of each part, it is necessary to plan what we need in every installation process like the spare parts, materials, tools, cranes, staff and time so as to greatly reduce the time and cost for installation and to ensure the finish of project on time.

3. 10-20 workers are required to form an installation team. And they must have over 2-year experience in machinery and steel industry. Besides, after the security training, they have a strong conscience of self-security. Moreover, related skills must be grasped well. Before working, they must wear all protective appliance like work clothes, safety helmet, safety shoes and gloves. Meetings about safety and quality requirements are held in advance and each individual’s working responsibility is assigned. The progress of project and related problems would be taken down every day and regular project meetings are held.

Customer Feedback

The project using sand and gravel tailings to make high-quality sand was offered by SBM. SBM offered both equipment and installation service. The whole process of installation was successful and VU120 system was put into operation on schedule. The operation was stable with little noises and no dust. The most important thing was that using the wastes produced by previous production to make valuable products brought us great economic profits.