Project Overview

From Project Design to Installation &Commission

This complete set of the anchoring agent production equipment is produced by SBM. With these machines, the production line is able to realize centralized-control, auto-production and auto-troubleshooting during the production process. Besides, it has advantages like easy operation, easy learning and use, etc.

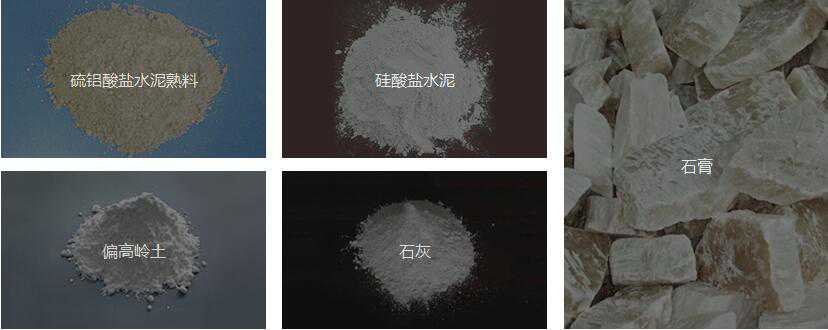

Material Features

Raw material: Sulphate-aluminium cement clinker, Portland cement, Metakaolin, Lime, Gypsum, etc

Inputting Size:<1mm

Moisture<5%

Application:Slip-casting &filling material

Final Product Requirements

| Raw material | Finished products requirements | Main properties | Setting time(min) | Compressive Strength(MPa) | Expansion Rate(%) | Anchoring force(KN) |

|---|---|---|---|---|---|---|

| Cement | 1250mesh D90% |

Satisty measure results MT219-2002 |

Initial set 3~4min |

0.5h >12~ 16 MPa |

0.5h≥ 0.1~0.18 | 0.5h ≥ 50~62 |

| Lime | ||||||

| Final set <7. 5min |

1h >18~ 24 MPa |

|||||

| Gypsum | ||||||

Production Requirements

1.No Grinding: After going through the weighting system, raw materials of anchoring agent are weighted and proportioned; then the materials are fed to the zero-gravity stirring system to be stirred; finally, they are sent by the pneumatic conveying system to finished product tank to be stored. When the finished products are packed in bags, they are able to be transported for sale.

2、Material Grinding: The raw materials are fed to the weighting system by the feeder to be weighted and proportioned, and then they are stirred and mixed in the zero-gravity stirring system. After that, the mixed materials enter the grinding system to be ground and classified. Finally, the materials are sent by the pneumatic conveying system to finished product tank to be stored, being packed in bags according to requirements.

Although, it needs two kinds of processing technology, the two sets of production processes share the same set of production line. With the high degree system integration, the production line takes quite little area and efficiently reduces total investment.

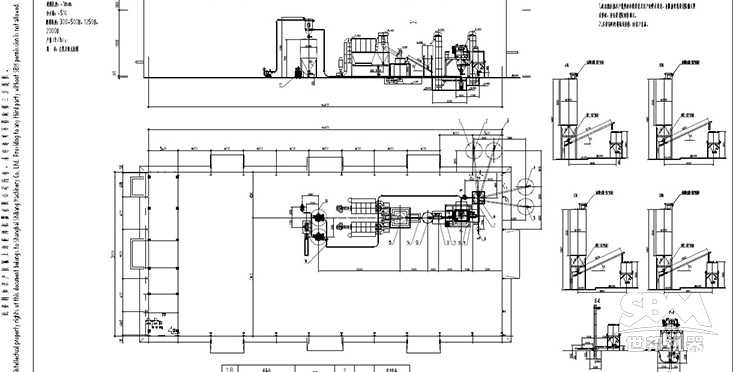

Equipment Configuration

Different from the standard design, this production line is improved according to customers’ requirements. The whole production line mainly contains the SCM1250 ultrafine mill (the main equipment), screw conveyer, powder packaging machine, pneumatic conveyer and so on, which meets the requirements of the two sets of production processes of anchoring agent.

The Main Equipments List

| No | Name | Model | Qty |

|---|---|---|---|

| 1 | Screw conveyor | LS315 | 2 |

| 2 | Scale | JLC | 1 |

| 3 | Screw conveyor | LSY250 | 4 |

| 4 | Hopper | 60m³ | 4 |

| 5 | finished product storehouse | 2 | |

| 6 | powder packing machine | 袋装 | 1 |

| 7 | pneumatic conveyor | QL | 1 |

| 8 | ultrafine mill | SCM1250 | 1 |

| 9 | spiral conveyor | LS219 | 1 |

| 10 | ore-surge bin | SCM1250-1 | 1 |

| 11 | bucket elevator | TH300 | 2 |

| 12 | material mixing system | WZ-6C | 1 |

| 13 | spiral conveyor | LS160 | 1 |

Standard equipment configuration table

| No | Name | Model | Qty |

|---|---|---|---|

| 1 | Motor of the mill | Y355M2-6 | 1 |

| 2 | Classifier | Y225S-4 | 1 |

| 3 | Elevator | TH-300 | 1 |

| 4 | Motor of the elevator | Y100M-4 | 1 |

| 5 | Feeder | Carina Belt Conveyor | 1 |

| 6 | Bunker(Silo) | 10m³ | 1 |

| 7 | Discharging Spiral Conveyor | LS219 | 2 |

| 8 | Discharging Valve | ZJD-250 | 3 |

| 9 | Blower Motor | Y250M-2 | 1 |

| 10 | Hammer Crusher | PC600×800 | 1 |

| 11 | Hammer Crusher Motor | YB2-280S-6 | 1 |

| 12 | Dust Collector | LDMC250 | 1 |

| 13 | Air Compressor | LG6.2/8 | 1 |

| 14 | Ultrafine Mill | SCM1250 | 1 |

Production Process

With the help of PLC and visualized operation, the degree of automation of the system is quite high. Benefiting from the SBM technology, the scheme configuration is very reasonable.

The first stage:

Feeding system: The cement, lime and gypsum and some other raw materials of the anchoring agent are fed to the weighting system through the feeder.

The second stage:

Weighting system: According to the set ratio, different raw materials are weighted.

The third stage:

Stirring system: After the weighting work, the materials are stirred and mixed in the zero-gravity mixer.

The fourth stage:

Grinding system: The mixed materials are fed into the ultrafine powder grinder through screw feeder to be ground and classified. As the key process, SCM1250 ultrafine mill grinds the powder into required 1250 mesh.

The fifth stage:

Conveying, storage and packaging system: Finished products are collected by pulse dust collector and sent to tank by the pneumatic conveying system, packed by packaging system and transported.

Why Chose SBM?

01 Integrative project design

SBM offers the professional project plan, including the working site scheme, the suitable machine configuration and the budget analysis and so on. What’s more important, they accept customized requirements in the project design.

02 High Automation

The whole production line realized centralized control by PLC, perfectly meeting the customer’s requirements, such as high efficiency, low pollution and low labor intensity.

03 Perfect Service

SBM has one professional installation engineer team. It can not only help customers finish installation work according to their requirements in short time, but also give a hand to train the operators.

04 Sustainable Services after Project Inspection

After the installation and commissioning, SBM Customers Security Department will be in charge of the follow-up services, including spare parts supplying, maintenance and upgrade, and working site revisiting, etc.

Advantages of Core Equipment

The main equipment in the anchoring agent production is SCM1250 Ultrafine Mill——

a high-efficiency but low-cost machine developed by connecting mill production experience and advantages of domestic and overseas mill manufacturing.

1. High Efficiency:Newly designed grinding roller, grinding ring and grinding curve can promote the grinding efficiency. Under the condition of the same fineness and power, the capacity of this mill is 40% higher than that of jet grinding mill &stirred grinder and more than twice that of ball mill; while the consumption of the system is only 30% that of jet grinding mill.

2. High Fineness:Both single-head powder separator and multiple-head powder selecting machine are optional. Because the speed of each rotor of the multiple-head powder separator is adjustable, the finished products can be collected directly, without further winnowing, and there is no inferior material. Among the final products, powders smaller than 2μm can reach 70%.

3. Highly Environmental Protection: The use of pulse dust collector, silencer and sound-proof room can remove dust and reduce noise, which is totally in keeping with the national standard requirements.

4. Low Cost: The grinding roller and ring are forged by using special materials. As a result, the service life is 2-3 times longer than that of impact crusher and turbo crusher under the same condition. And it reaches 2-5 years when it is used to grind calcium carbonate and calcite.

Customer Feedback

"After the site visit and test, the engineers from SBM offer us a quite perfect design. Finally, we accept their design, using SCM1250 as the main equipment. Now the equipment is running well, and the high capacity, quality and stability are exactly what we need. SBM products do deserve the reputations they enjoy."