Project Overview

Scheme design— installation and commissioning

This energy enterprise is the R&D base of coal clean & efficient utilization in Shandong, the micro-coal pulverization technology of which can greatly promote the transformation and upgrading of coals. During the process, the micro-coal is the pulverized particle processed by mills to meet fineness requirement. The line makes fuels combine with air by pulverized technology and after rotary current appears, the fuels conduct float combustion in the industrial boiler and reach high-efficient combustion by thermal, measurement & control and exhaust gas purification systems at natural gas emission levels. The 4 sets of MTW and auxiliary equipment are used for pulverized coal production, which can not only improve input-output ratios, but also greatly ease emissions of dust, sulfur dioxide and nitrogen oxides.

Project Background

According to reports of Coal Association, more than 70% coal enterprises are faced with grim situations --- losses which make the transformation of the coal industry urgent. So, under the premise of controlling total amount of coal consumption, how to improve economic benefits of traditional coal enterprises, how to utilize coal resources efficiently and how to reduce coal pollution on environment have become the problems explored by many enterprises.

Coal Enterprises in “Cold Winter”

According to reports of Chinese Coal Association, over 70% coal enterprises are faced with grim operation situations --- losses. Meanwhile, the country is also actively promoting market-oriented reforms and structure adjustment of coal industry at the policy level. Under the context of disentangling relationship between supply and demand, the transformation of the coal industry becomes urgent.

National Policy Support

National Energy Administration recently released Action Plan on Clean & Efficient Utilization of Coal (2015-2020), which stipulated key tasks in 7 aspects. Of them, efficient boilers in partial areas should be up to above 50% by 2020. The Fifth Plenary Session of the Party’s Eighteenth Conference proposed promoting clean& efficient utilization of fossil energy. Obviously, efficient and environmental coal boilers are key energy-saving technology projects promoted by our country.

Local Government Support

Shandong government provides subsidies for some key PPP projects at early stage. Meanwhile, the government announces the notice to formulate efficient and environment-friendly coal boiler promotion action plans (2016-2018): the boiler is mainly used for steam and heat supply and focuses on “five-one project” to accelerate popularization and application of it.

Environmental Pressure

The traditional industrial boiler adopts bulk coals as fuels with large emissions of smoke and gas pollution, while if it adopts pulverized coal as fuels ---- smoke dust ≤30mg/m3, sulfur dioxide ≤100mg/m3, nitric dioxide ≤200mg/m3, which are below national emission standards and meet local environmental demands.

Economic & Environmental Benefits of Coal Combustion

When the traditional coal-fired boiler is transformed into pulverized boiler, the coal combustion efficiency is higher than 98%, thermal efficiency higher than 90% compared with traditional ones. The comprehensive operation cost declines by 20-30%. Compared with natural gas boiler, the fuel procurement cost of pulverized coal boiler is about 1/3 of that of natural gas boiler.

Performance Standards

Project Location: Shandong, China

Material: Coal

Finished Product: Pulverized coal

Input Size:<50mm

Output Size: 200 mesh D80%

Capacity: 1,000,000TPY

Equipment: 4 sets of MTW215 Euro-type Mill (the second phase), the auxiliary feeding, pulverizing, dust removal, powder collecting, transportation, storage and nitrogen protection devices.

Host Devices of Pulverized-coal Preparation System

4 sets of MTW European Mills (the second phase): The integrated system of MTW European mill is the new generation of grinding equipment with world’s advanced level. The equipment adopts bevel gear transmission as a whole, internal thin oil lubrication system, online measuring of oil temperature and many other advanced technologies with multiple intellectual property rights. The whole system has the advantages of small occupying areas, less comprehensive investment, low operation costs, high efficiency and environmental protection and so on.

System composition: Raw coal bunker, Weighing coal feeder, MTW Mill, Powder concentrator, Fan, Iron separator, Drying system, Conveying system;

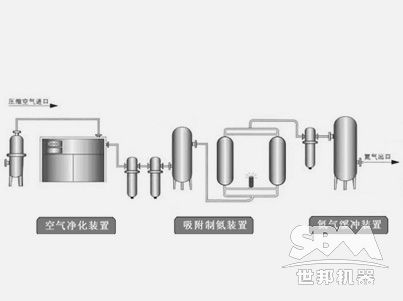

Nitrogen-making system

After being compressed by compressors, the air enters into high-efficient degreaser to remove most oil, water and dust; then it enters into frozen air-dryer to remove a lot of water, then enters into dust filter to remove dust, and finally enters into gasholder for buffering as well as oxygen & nitrogen separation system of adsorbents, namely nitrogen-making machines. Clean compressed air enters from the bottom of the adsorbent; the airflow evenly enters the adsorbent after air dispersion with nitrogen flows out from the outlet into the nitrogen gas buffer tank.

Fire Extinguishing System

When temperature inside the protection zone exceeds default alarm temperature, the alarm signal will be delivered to the host alarm; when the host alarm gives orders, the alarm ring will give an alarm and the carbon monoxide concentration alarm signal will also be connected to the fire-alarm host through signal lines; when the carbon monoxide concentration is more than the default alarm concentration, the sound & light alarm will begin to alarm and the alarm host will start 30s delay reverse; when it reverses to 0, the host alarm sends signals to carbon dioxide fire-extinguishing system and the nitrogen-cylinder starts to open corresponding magnetic valve, namely the nitrogen starts this system to extinguish fire. The system has four control methods, including automatic, manual, mechanic emergency hand-control and urgent stop & start.

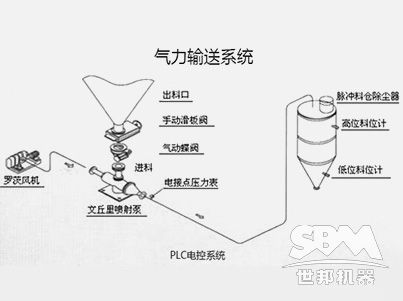

Pneumatic Conveying System

The pneumatic conveying system can realize long-distance transportation by conveying coal into storage tank of finished products.

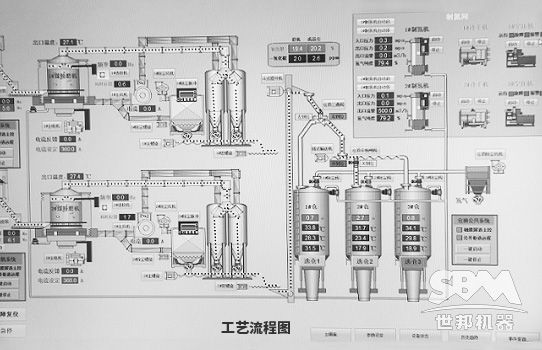

Intelligent Central-control System

With the industrial computer as the core unit of the whole system, the central-control system can read out PLC or ECS through various communications technologies. It can control on-site equipment according to instructions from computers through acquisition of equipment status, thus realizing such functions as remote control of equipment, record & analysis of equipment information and printing of operation reports of equipment.

MTW European Mill is equipped with expert intelligent-control system designed especially for mills and adopts ESC intelligent control, which can realize both remote and central control by phones, ipad and other mobile devices, namely realizing the check of operation situation.

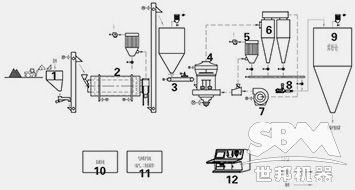

Process Analysis

The raw material in the storehouse is conveyed to the scraper conveyor through the quantitative belt feeder and is dried up in the dryer, and then it is conveyed to the enclosed storehouse through sealed scraper conveyor and transferred to the warehouse by carrier vehicles and finally fed into the inside of MTW215 mill through weighing coal feeder. After being classified by powder concentrator, the ground powder enters into powder collector along pipes (residual air is collected by pulse dust collector). The collected finished coal powder enters into the coal elevator through spiral conveyor system for storage and is transported by tankers based on demands. The complete system is added with nitrogen-making system and carbon dioxide system to provide explosion-proof and extinguishing protection and explosion-proof valve is installed on key parts to prevent equipment damage.

Project Advantages

EPC Service

In order to minimize construction period of project and reduce customer investment, this project adopts EPC service. It is a “turnkey” service designed especially by SBM targeting at customer demand --- production convenience. The service runs through all parts, including environment surveys, process design of production lines, test of raw materials, analyses of finished product, budget of investment costs, equipment installation & debugging, thus avoiding input delay for lack of construction materials and human resources. The EPC service has maximized production convenience and satisfied emergency needs of customers, which also receives high praise from customers in Shandong.

Convenient Operation

To improve operation performance of coal production line, this production line adopts unique two-step operation --- drying and milling. The two-step system refers to the solution to separating drying and pulverizing with lower temperature of grinding chamber. This preparation process is unique to MTW European Mill --- relatively simple and easy to control, which can greatly improve safety performance of the production line.

System composition: Raw coal bunker, Dryer, Weighing coal feeder, MTW Mill, Pulse dust collector, Powder collector, Fan, Coal bunker of finished product, Pulverized coal bunker, Monitoring system, Explosion-proof system, Central control system;

Small Investment

MTW mill adopts bevel gear transmission as a whole, internal thin oil lubrication system, online measuring of oil temperature and many other advanced technologies with multiple intellectual property rights. The whole system has the advantages of small occupying areas, less comprehensive investment, low operation costs, high efficiency and environmental protection and so on.

Security and Environment-protection Performance

To ensure the fire-proof and explosion-proof performance of coal during preparation process, the production line is equipped with the nitrogen gas and carbon-dioxide extinguishing system to guarantee safety and stability of equipment in operation.

Meanwhile, effective measures are taken to strictly control dust emissions within regulated range. The production line also adopts advanced pulse dust collectors to reduce its effect on surroundings.

Benefit Evaluation

Economic Benefit Evaluation

To reform the traditional coal-fired boiler with micro-coal atomization technology can improve combustion efficiency up to 98% and heat efficiency to 90% and improve tons of steam from 5.5tons to above 9 tons. Compared with the traditional coal-fired boiler, this technology can save over 30% coals, 20% electricity, 10% water, 60% land and 50% human resources; the coal sales reach 0.8 billion and profit tax reaches 0.1 billion.

Social Benefit Evaluation

The pulverized coal produced from this line is supplied for industrial boilers through micro-coal atomization technology, which has broken the traditional coal combustion status in bulks. So, it becomes the model of efficient and clean coal utilization and promotes the transformation of coal, which has great implications for coal enterprises to go through the cold winter.

Environmental Benefit Evaluation

Various air pollution indicators have reached emission standard of natural gas boilers and realized no dust, slag or smoke.

Customer Feedback

As this coal production line was large and we had strict demands on coal quality, we were very prudent in the choice of manufacturers. After long-time consideration and inspection, we finally chose SBM which gave us professional solutions and services from on-site investigation to installation & debugging. The 4 sets of MTW we purchased are running very well with production beyond designed capacity.